Research groups

Polymer matrix composites

Composite materials are a group of innovative structural or functional materials widely utilized in many industries, e.g., aviation, automotive, public transportation, machine building, as well as sport goods.

Non-Ferrous Metals And Their Alloys

Our team has long-term experience in metallic materials designing and testing, especially titanium and its alloys, which is confirmed by the participation in many R&D projects, also international ones.

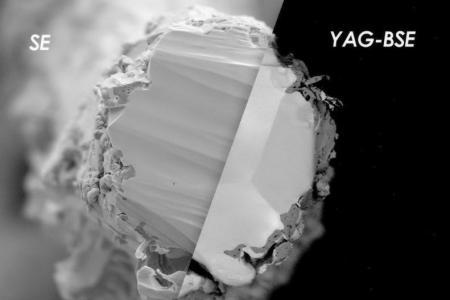

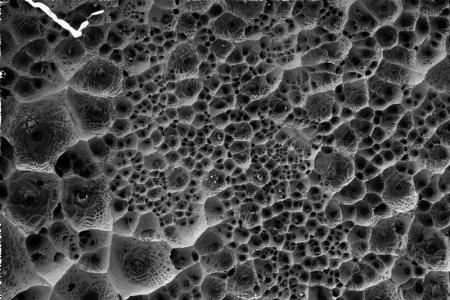

Ceramics, ceramic-metal composites and biomimetic materials

Optimization of ceramic-metal composites fabrication. Influence of the metal phase on the microstructure and properties of composites. Ceramic-metal interface.

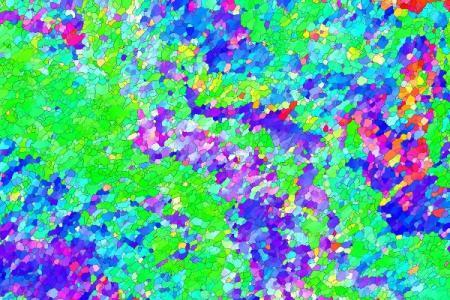

High Entropy Alloys

High Entropy Alloys (HEA) are multicomponent metallic alloys consisting of at least 5 elements in equimolar or near equimolar proportions, showing simple phase composition and unique properties.

Prof. Marcin Leonowicz

The team specializes in shaping the structure and microstructure of structural and functional materials.

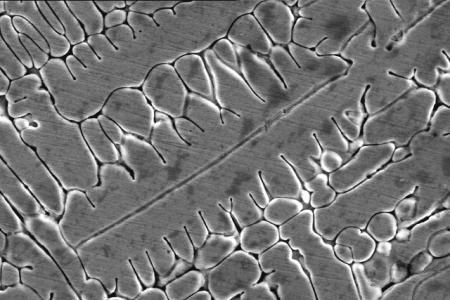

Nanocrystalline and ultrafine grained materials

Nanocrystalline and ultrafine grained materials are a new class of structural and functional materials characterized by a polycrystalline structure with a grain size of hundreds of nanometers (ultrafine grained materials) or tens of nanometers (nanocrystalline materials).

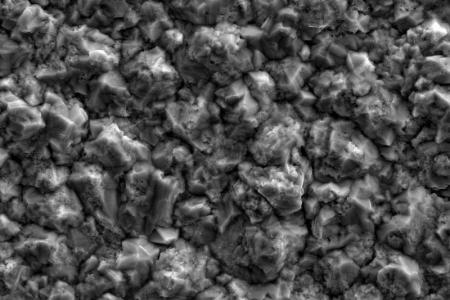

Characteristics of materials after plastic deformation

The research work focuses mainly on the processes of severe plastic deformation and the accompanying effects of microstructure and properties changes.

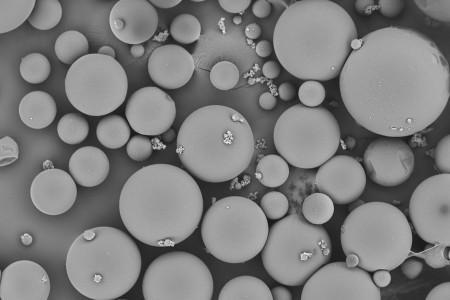

Mechanical alloying and powder sintering

Fabrication of alloys and composites by mechanical alloying and sintering of the obtained powders, structure and properties studies of powders and sinters.

Mechanical properties

The group’s main activity is related to the topic of mechanical properties testing of materials, both in accordance with standards and non-standardized tests.

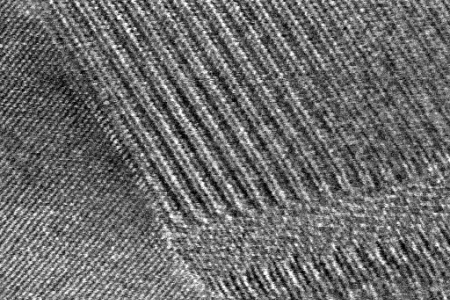

Polymers

The research group specializes in analysis of the relationship between the structure and properties of various polymer materials. For many years, the group has been dealing with applications of various groups of polyurethane materials.

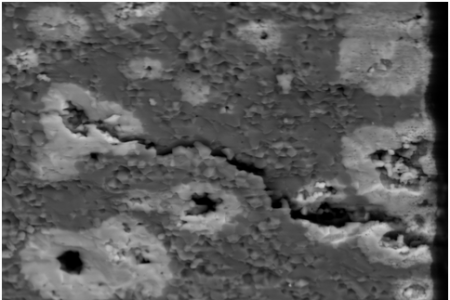

Electrochemical and chemical treatments

The coatings can be divided in terms of the way they are produced into electrolytic coatings - galvanic (nickel, copper), coatings deposited by chemical reduction (nickel, phosphorus and zinc), chemical conversion coatings (phosphate) and coatings produced by electrochemical anodic oxidation and plasma electrolytic oxidation.

Biomaterials

Biomaterials constitute a specific group of materials with different composition and properties that are designed to interact with elements of living systems to influence therapeutic or diagnostic processes, as independent entities or in complex systems.

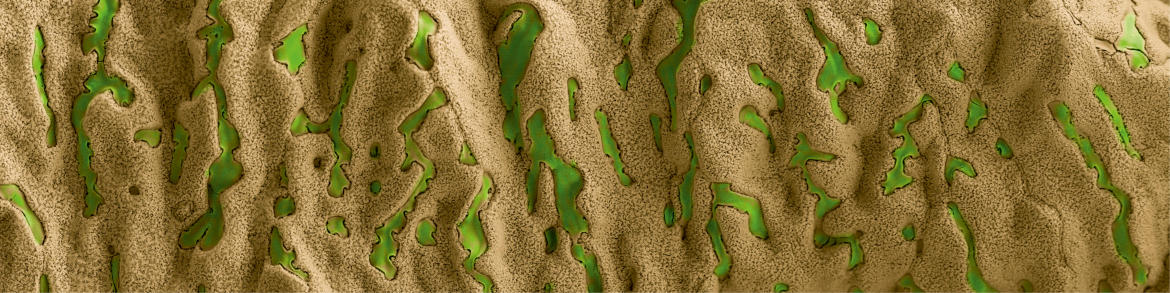

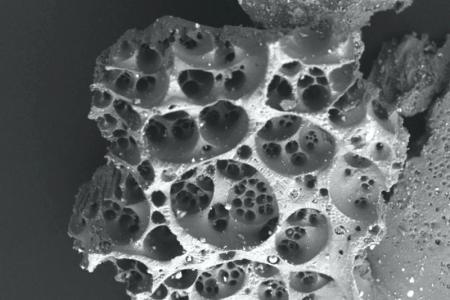

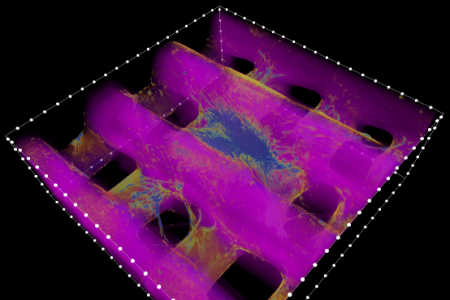

Porous materials team

The Team is a part of the Division of Materials Design of the Faculty of Materials Science and Engineering at the Warsaw University of Technology. Its research is focused on high porosity materials. The activities of the team include production, characterisation and numerical modelling techniques in order to design the microstructure and properties of porous materials and the processes taking place in them.

NANOSTAL – technologies of heat and thermochemical treatment

The interest of our group focuses on shaping mechanical and functional properties of steel via selection of chemical composition and heat treatment to obtain optimal phase composition and microstructure.

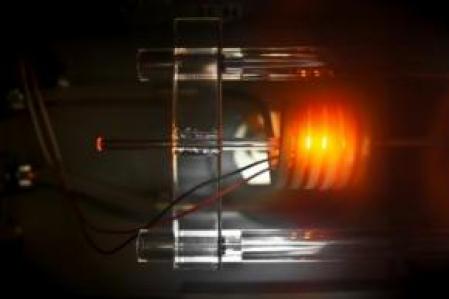

Materials for power industry

The research carried out in the group covers a wide range of issues related to modeling, manufacturing and characterization as well as practical use of materials for modern energy production systems.